Power Plastics

Pre-filtration and Filtration of Drinking and Process Water

|

Automatic Self-Cleaning Screen Filters With Large Filtering Capacity |

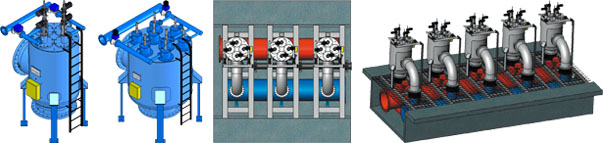

Automatic self-cleaning screen filters of the TWIN and MEGA series are an economic and very efficient solution for filtration of large water volumes.

Automatic self-cleaning screen filters of the TWIN and MEGA series are an economic and very efficient solution for filtration of large water volumes.

They are a suitable alternative to the system of multiple automatic filters of the AF-800 and AF-900 series connected in a parallel way. One filtration body is equipped with two or four filtration screens with a self-cleaning mechanism [suction jets or brushes], which means significant savings of space necessary for installation. The filtration capacity is virtually unlimited.

Typical applications:

- Metallurgical industry: cooling towers, filtration of scales from water for cooling of ingots, sheet …

- Power engineering: cooling towers, sprinkling of coal to reduce dust formation, cooling of gas storage systems …

- Agriculture: water filtration for large-capacity irrigation systems

- Pre-filtration of sea and river water …

Standard Features:

- Minimum operating pressure: 16bar

- Clean filter pressure loss: 0.1bar

- Maximum water temperature: 95°C

- Filtration range: 10 - 3000 micron

- Filter housing materials: carbon steel coated with baked on epoxy, stainless steel 316L or 316Ti

- Filtration capacity of the filter: < 12.000m³/h

- Automatic control unit

|

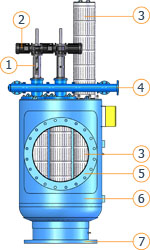

TWIN Filter AF-900-TW Filter housing materials: carbon steel |

|

Filter AF-MEGA 800 Filter housing materials: carbon steel |

|

Filter AF-MEGA 900 Filter housing materials: SST 316L |

TWIN FILTERS

SERIES AF-800-TW

|

Model |

Conn. Size [inch] |

Screens Area [cm²] |

Maximum Flow Rate [m³/h] |

Flushing Flow Rate [m³/h] |

|

AF-808LOPR-TW |

10-12 |

16 820 |

600 |

60 |

|

AF-810PR-TW |

12-14 |

16 180 |

700 |

120 |

|

AF-810LOPR-TW |

12-14 |

16 820 |

800 |

60 |

|

AF-810XLP-TW |

12-14 |

23 420 |

900 |

180 |

|

AF-812PR-TW |

14-16 |

22 340 |

1 200 |

180 |

|

AF-814PR-TW |

16-20 |

25 980 |

1 800 |

180 |

|

AF-816PR-TW |

20 |

25 980 |

2 200 |

180 |

|

AF-816XLP-TW |

20 |

34 040 |

3 000 |

180 |

SERIES AF-900-TW

|

Model |

Conn. Size [inch] |

Screens Area [cm²] |

Maximum Flow Rate [m³/h] |

Flushing Flow Rate [m³/h] |

|

AF-903PR-TW |

4 |

6 440 |

100 |

20 |

|

AF-904PR-TW |

6 |

9 000 |

160 |

20 |

|

AF-906PR-TW |

8 |

12 660 |

360 |

20 |

|

AF-908PR-TW |

10 |

14 060 |

700 |

20 |

|

AF-910PR-TW |

12 |

17 940 |

900 |

20 |

|

AF-912PR-TW |

14 |

21 840 |

1 200 |

20 |

|

AF-914PR-TW |

16 |

23 520 |

1 700 |

20 |

|

AF-916PR-TW |

20 |

28 620 |

2 200 |

20 |

|

Installation possibilities |

|

|

Vertical installation of the filter on a pipe |

Horizontal installation of the filter on a pipe |

|

|

|

|

1. Filter 2. Contaminated water inflow 3. Filtered water outflow 4. Shut-off flap valve for by-pass 5. Shut-off flap valve on the inflow 6. Shut-off flap valve on the outflow |

1. Filter 2. Contaminated water inflow 3. Filtered water outflow 4. Shut-off flap valve for by-pass 5. Shut-off flap valve on the inflow 6. Shut-off flap valve on the outflow |

MEGA FILTERS

SERIES AF-MEGA 800

|

Model |

Conn. Size [inch] |

Screens Area [cm²] |

Maximum Flow Rate [m³/h] |

Flushing Flow Rate [m³/h] |

Flushing Time [s] |

Body ØD [mm] |

Weight [kg] |

|

AF-MEGA 812 |

16-32 |

40 000 |

4 000 |

100 |

60 |

1 250 |

1 800 |

|

AF-MEGA 816 |

16-32 |

52 000 |

5 200 |

100 |

60 |

1 400 |

2 000 |

SERIES AF-MEGA 900

|

Model |

Conn. Size [inch] |

Screens Area [cm²] |

Maximum Flow Rate [m³/h] |

Flushing Flow Rate [m³/h] |

Flushing Time [s] |

Body ØD [mm] |

Weight [kg] |

|

AF-MEGA 912 |

16-32 |

40 000 |

4 000 |

100 |

60 |

1 250 |

1 800 |

|

AF-MEGA 916 |

16-32 |

52 000 |

5 200 |

100 |

60 |

1 400 |

2 000 |

|

|

Legend:

|

|

Installation possibilities |

|

|

Installation of the filter in the pipeline [in-line] |

Installation of the filter on the pipe [on-line] |

|

|

|

|

1. Filter 2. Contaminated water inflow 3. Filtered water outflow 4. Shut-off flap valve on the inflow 5. Shut-off flap valve on the outflow 6. Non-return flap valve 7. Mud hole 8. Servicing hole 9. Automatic valve for the drainage of impurities from the filter bottom |

1. Filter 2. Contaminated water inflow 3. Filtered water outflow 4. Shut-off flap valve on the inflow 5. Shut-off flap valve on the outflow 6. Non-return flap valve 7. Shut-off flap valve for by-pass |

Although the filters are manufactured in a top technical and technological quality, their installation, operation and maintenance are very easy. They are intended for a continuous operation and are non-demanding in terms of both rinsing water consumption and consumption of energy.

If you require removal of any mechanical impurities from water, please contact us and we will draw up, free of charge, a proposal for the most suitable solution for you, on the basis of a raw water analysis, required filtration capacity [m³/hr] and required quality of output water.

|

High Quality Water No Matter Where It Comes From |

FILTRATION & WATER TREATMENT

EXCELLENCE IN

DESIGN & MANUFACTURING

tel./fax: +420 566 630 843

gsm: +420 775 630 843

Welcome to the website of Power Plastics s.r.o.