Power Plastics

Power Enginnering & Metallurgy

|

Application: |

Power Station - Filtration of hot process water from boilers [120m³/hour] |

|

Treatment Process: |

Sedimentation, filtration with sand filters and active carbon filters, reverse osmosis [RO], electro-deionization [EDI] |

|

Results: |

Ultra-pure water |

|

Application: |

Power Station - Water treatment for gas turbine process [5 units in different sites, 25m³/hour per unit] |

|

Treatment Process: |

Filtration through sand filters, reverse osmosis double pass system, gas removal and EDI |

|

Results: |

Supplying good quality water for the gas turbine operation |

|

Application: |

Filtration of water for cooling towers in a gas plant [4000m³/hour] |

|

Treatment Process: |

Removing particles from the cooling water. On-line automatic electric self-cleaning “MEGA” filter with four stainless steel filter screens |

|

Results: |

Process water without mechanical impurities for reuse in cooling system |

|

Application: |

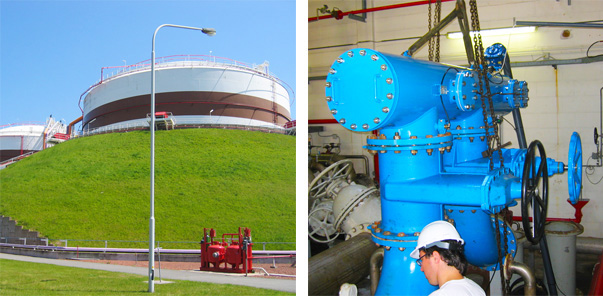

Gas tanks cooling system and fire protection system [1200m³/hour] |

|

Water Source: |

North Sea |

|

Treatment Process: |

High pressure automatic hydraulic self-cleaning filter AF-816XLP with increased filtration area, and special seawater resistant finish |

|

Application: |

Pre-filtration seawater for the needs of a electric transformation platform [1400m³/hour] |

|

Treatment Process: |

2 x automatic electric self-cleaning filter AF-910, fully rubber lined, screen of corrosion high resisting stainless steel 254 SMO |

|

Application: |

Steel Mill - Industrial wastewater from coal-washing process highly contaminated with coal dust [2.000-4.000PPM]. Traditional treatment contaminates water with additional chemicals [total capacity 90m³/hour] |

|

Treatment Process: |

Chemical-free electro-coagulation treatment system using an electrolysis process with sedimentation and fine, deep filtration |

|

Results: |

98% of the wastewater is now crystal clear and purified to the level of 0.1 NTU. The water is recycled and the treatment system easily maintained |

|

Application: |

Steel Mill - Treatment of process water [5400m³/hour] |

|

Treatment Process: |

Remove pieces of metal and other impurities contaminate cooling water using as a cooling medium for hot metal plates. Four filter circuits, each with three automatic self-cleaning electric filters AF-910PR |

|

Results: |

Elimination of staining on a hot steel plates, improve the quality of production by 64%. Significant time savings in the maintenance of cooling towers |

|

Application: |

Steel Mill - Filtration of cooling water used in the manufacture of steel sheets and ingots [6000m³/hour] |

|

Treatment Process: |

Removal of metal fragments and other debris from the water coolant. On-line automatic electric self-cleaning “MEGA” filter with four stainless steel filter screens |

|

Results: |

Process water without mechanical impurities for reuse for cooling in steel production |

FILTRATION & WATER TREATMENT

EXCELLENCE IN

DESIGN & MANUFACTURING

tel./fax: +420 566 630 843

gsm: +420 775 630 843

Welcome to the website of Power Plastics s.r.o.